Have you heard of aluminum extrusions? Well, if you have a keen interest in modern construction and industries, it is likely that you have seen the revolutionary designs and products in the modern construction landscape—but what really are they and how are they made?

These units are made using specific extrusion machines. If you are thinking of getting these units, we will outline the best ones and how much you need to have one.

Let’s get going!

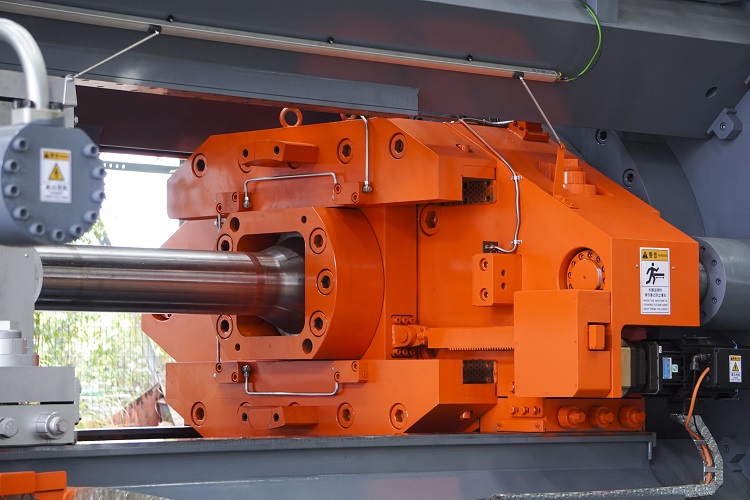

An extruder machine is simply a groundbreaking tool used to force metal through a unique matrix to mold it into a predetermined shape. The end products (aluminum extrusion metals) are then finished into various usable measurements in the construction and building industries among others.

Every extrusion is made using specific processes and of course devices. With this in mind it is important to understand that you can use aluminum alloys as a guide to help you choose the suitable machine option. For instance, if you want to generate subtle alloy pipes, a classic single action (forward) extrusion machine is your best option.

When shopping for your extrusion machine, these are the most popular options in the market to consider:

1. Cold Machines: These extrusion machines operate at standard room temperature rendering them ideal for generating quality finish basic alloy shapes.

2. Hot Machines: Another option is the hot extrusion aluminum extrusion devices. These units are made to generate aluminum profiles mandating high temperatures. What’s more, they are suitable for complex and massive cross-sectional profiles.

3. Indirect Machines: As the name suggests, these units popularly called indirect aluminum presses operate in a unique manner.

Like with many other devices, the overall cost of aluminum presses usually varies depending on various factors like complexity, size and even capacity. Generally, the basic cost of these machines can range from between $ 30,000 to over $1000000 per set.

As aforementioned with the different types of aluminum extruders available, it is important that you conduct comprehensive research across various avenues and compare different features and models to identify the most suitable extrusion machine for you.

Checkout this detailed list of the most popular extruder options and their overall pricing.

These are remarkable presses that come with a unique heating bed, run out tables, aging furnaces and heating pullers. The primary advantage of these machines is their efficiency and robustness. The basic cost of these machines ranges from $200,000 to around $600, 000, a cost that usually depends on the brand and the additional tooling.

The difference between these machines is their output with the 800T being significantly more powerful than its counterpart. However, if you want to generate mild, yet quality extrusions, these are the most suitable options.

Similar to the extrusion machines mentioned earlier, these machines also come with basic features like cooling beds, run out tables, heating ovens for the mold, and of course furnaces. However, since these machines are rated higher in power and capacity, they are of course relatively costlier than the previous models.

The 1000T machines are more versatile and can generate more robust and complex extrusions. These presses have a price range of between $400, 000 and $800, 000—a meager price adjustment considering the power generated.

Finally, the most powerful units in this category come with stunning power and capabilities. These units are designed to offer superior quality and durable extrusions of different shapes and considering their remarkable capacity and essential attachments are quite costly, though a worthwhile investment. As earlier outlined the cost of these units mainly depends on auxiliary parts and manufacturer. The basic range is between $500, 000 to over $1,000,000.