Imagine a device that can change molten metal into complex building blocks or amorphous dough into your favorite brand of breakfast cereal. This is not fiction, but the amazing field of extrusion.

The machine itself is often less important than what it produces, because, in so many ways, the extruder is a revolutionizing technology which shapes our daily living.

Therefore, what does the extruder exactly do? What are working principles, mechanics and applications of these machines? Let’s see.

At its core, it is more than just pushing a material through a mold; it involves forced flow where “material” can range from molten plastics and metals to pastes, doughs and even biomaterials. Here we go beyond the “mold” to an accurately engineered die that dictates ultimate shape. This is where wonders happen.

The extruders use different methods to create controlled pressure that forces material through the die. Such forceful flow does not only shape materials but also changes their properties based on application requirements.

For example, food extrusion creates porosity in cereals whereas the strain hardening that occurs during metal extrusion improves metal strength. Developed continuously; some extruders have now reached 10 000 tons pressure at most. This allows them to create massive products, like pipes with diameters wider than a car!

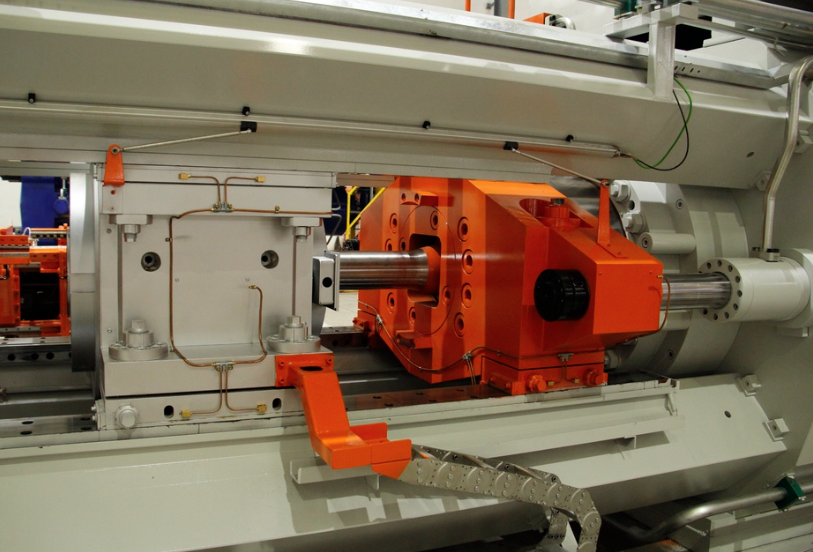

Though the details differ depending on the material and machine type, there are several basic parts of an extruder that are common to most machines.

Feed hopper: Material is loaded into the extruder through a precisely controlled feeding system from this starting point, which is a feed hopper. This could be in the form of pellets, powders, or even pre-mixed blends; it’s a raw material that will travel through the extrusion process with faultless supply.

Screws: Rotating screws found in screw extruders have numerous roles such as feeding, mixing and often melting of materials as they advance towards the die. There are various screw designs where changes in its length, diameter, number of threads determine actions such as mixing efficiency, pressure generation for complex shapes and overall production rate.

Barrel: If present, this heated chamber surrounds the screw until the material achieves suitable consistency for smooth extrusion. The temperature along the barrel is raised due to heating elements present together with frictional heat generated by rotation of screw. At times there can be cooling zones within barrel for specified applications.

Die: For shaping purposes, die acts as important because it is made up of metallic mold that eventually determines how an extruded product will look like. Factors considered in the design die include pressure distribution, flow properties of material, and desired product dimensions achieved with high precision.

Die designing is facilitated by sophisticated computing applications that help to model dies. The software replicates the flow of materials inside the die, which helps engineers to optimize its geometry for improved product quality and accurate dimensional control.

Extrusion has more than a few basic machine types. Here is a sneak peek at some the impressive examples:

Food to Fashion: These food extruders make your favorite cereals as well as pasta shapes, sweets and even some pet foods. It may come as a surprise but this technology is also used in producing synthetic fibers for clothes by textile industries!

Building Our World: In construction, extrusion plays an important role in creating weather-resistant building materials such as cladding or window profiles. Additionally, it is used in plumbing and electrical fittings.

Medical Marvels: Extrusion is widely applied in medicine when it comes to creating tubes for catheters and other important medical devices. Further still, this technology may be used during some 3D printing processes where customized implants are made through extrusion.

The Green Revolution: The focus is shifting towards sustainable development; therefore, biotechnological extrusion is considered a breakthrough in technology. Bio-based components such as algae or food waste are used in this process to create sustainable packaging and other products that reduce the dependence on conventional plastics.

Thus, the global extrusion market for the year 2025 is estimated at 140 billion dollars and above which emphasizes its importance in various industries.

Extruders are not just machines, but they form the basis on which everything unfolds from our meals to our homes. With advances in materials science and new applications unfolding, it is certain that extrusion technology will continue to change over time, creating future one precisely molded product at a time.