You have a lot of choices when it comes to aluminum extrusion. As you focus on producing attractive metal parts for your consumers and keep up with the market speed, aluminum quietly does its job in ensuring your manufacturing operation runs smoothly.

Affordability is the backbone of any production process, hence the proven popularity of aluminum extrusions. Also, raw materials take up most of the expenses during the extrusion process; understanding how to lower this cost is all you need to make a big difference in your operating expenses.

Of course, there are other methods of reducing cost while producing intricate aluminum profiles and bulky orders of duplicate parts. Let's dive right into some of the ways you can reduce the cost of producing aluminum extrusion.

While starting an aluminum extrusion business, the first thing you should think about is the strengths of using this material and how it plays out in terms of production cost and other advantages like:

● The outer surface of the aluminum allows for better protection by facilitating corrosion resistance.

● You can produce lightweight extrusions thanks to the lower strength to weight ratio compared to its counterparts like steel.

● Aluminum is recyclable; hence its abundance and reduced extrusion cost.

● The metal is very workable, so you can easily produce intricate parts.

● Aluminum has good electricity and heat conductivity.

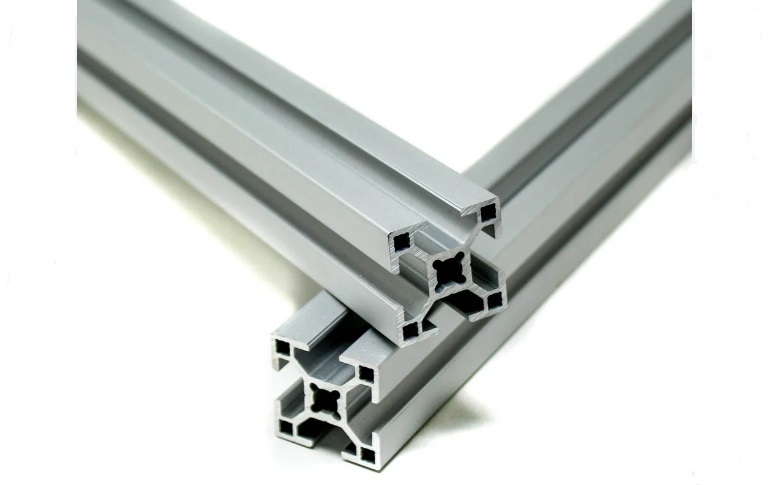

Extrusion basically allows for the formation of the metal into different profile shapes. The production process is suitable for both pure aluminum and its alloys. There are other processes used in metal work. Still, when you combine the good properties of aluminum and the efficiency of the extrusion process, the benefits are endless compared to other manufacturing operations like casting parts and welding. Let's look at some benefits, shall we?

● Reduced manufacturing time.

● Allows for same cross section custom or standard profile designs.

● Extrusion equipment is more energy efficient and long-lasting compare to other methods.

● The extrusion process is more cost effective than other methods.

● You can integrate aluminum extrusion with other manufacturing processes.

Aluminum is charged per metric ton. This cost is affected by a wide range of factors which is why, one moment the prices are affordable and constant; other times. they are over the roof.

Given that aluminum is the raw material for the extrusion process, the wild fluctuations of its price also affect the production cost. Other factors are:

If you are just getting your bearing in aluminum extrusion, you should consider all the design requirements of your customer before giving a quote. Why? You might wonder, well

Profiles have different design features; complex designs will cost you more to produce than straightforward ones.

An expert extruder can be very helpful on profile design, especially if you’re new to extrusion. Often, subtle differences in a profile’s design lead to substantial differences in cost. Manufacturing a large number of extrusions with the same design costs less in the long run, but the design freedom involved in aluminum extrusion helps you cater to even the most complex design requirements of your clients.

The durability of aluminum profiles even before finishing is guaranteed. Nevertheless, you can go all the way when it comes to enhancing the visual appeal of the profiles during applications.

There are endless possibilities when it comes to finishing techniques and color options suitable for aluminum parts. The ideal choice boils down to customer demands or application requirements.

Emerging trends, political factors, inflation in electricity cost, etc. are just a few parameters with an impact on the cost of the aluminum raw material for extrusion. You can be on the safe side by bulk buying the material for your business when the prices are most favorable.

You should factor in the aluminum grade suitable for your project as they come at different costs. Sometimes, the alloy requirements of your customer are too unique so you have to request a custom order, which might be more expensive.

Large scale aluminum extrusion manufacturers save more on the production process than small volume projects. Custom aluminum extrusion incurs a cost similar to that of bulky production because of the cost of buying the die and tooling required. The cost of producing each part of a custom project is higher than that of the same quantity of a standard profile.

There are universal guidelines on the tolerance of standard aluminum extrusions. However, at the end of the day, the extruder has the ultimate decision on whether to alter the standard tolerances. For this reason, ensure there is proper communication between you and your customers on the aluminum profile features required and the production cost.

With the increase in aluminum prices in the last two years, it is essential to use ways of saving as much as possible during the production process. This allows you to keep up with the fluctuating prices while increasing the yield of your business. Let's explore some of the cost-effective solutions:

If you keep producing aluminum profiles with defects, you might end up increasing the production cost because of the high amount of scrap and conversion expenses. For these reasons, ensure you explore the different types of defects mentioned later on in this article so that you can apply every prevention measure.

Engaging with suppliers that have a greater extrusion capacity and high efficiency equipment is an effective strategy to adding value to your product development. Suppliers are also suitable candidates for such a partnership as they have the knowledge on the most suitable alloys, designs, and your production process. Ensure the partner you involve is at par with your business goals, and requirements.

There are limitless options when it comes to aluminum alloys suitable for the extrusion process. Think of your process requirements, machinery available, customer needs, and budget before you settle on the alloys.

Alloys come at different prices depending on their properties, like sturdiness and aluminum content. Those with a higher percentage of pure aluminum come at a higher cost.

It is important that you know the exact amount of scrap from your aluminum extrusion process. Most extruders opt to sell the scrap to avoid the cost of conversion.

In such cases, you should be able to determine your profit by evaluating the earnings from the scrap against what you paid for the raw materials.

Alloys used for producing standard aluminum profiles are readily available in the market. For instance, the 6061-T6 alloy is cost effective, and it allows for great workability and medium strength. If you are producing aluminum extrusions for less demanding applications, making simple designs is the easiest way to cut on the production cost. The cheaper the alloy, the higher the machinability.

Technological advancements have paved the way to the availability of better equipment which reduces production time and labor expenses. Automation is another advancement that allows for the use of software to send direct signals during operation.

Optimization allows you to automatically select the profile length you want to produce, track different aspects of the production process, as well as predict and prevent production issues. This reduces the amount of scrap in the long run and other expenses.

Aluminum extrusion molds come at different prices, depending on their quality. If you are just starting up, you can outsource advanced profile molds to improve your production process.

There are various parameters that affect your production capacity, machinery, and experience as an aluminum extrusion manufacturer. The right choice of aluminum extrusion machinery is a great step towards reducing the expenses of the operation.

On that note, it is worth noting that the die takes up a significant amount of the start-up money. Nevertheless, you will be able to produce quality standard and custom products for your clients, whether you are working on large scale or small-scale projects.

Additionally, you can increase the affordability of the operation by reducing the lead times and investing in a top-quality die. A cost-effective extrusion project offers the possibility of easy prototyping and adjustments required.

If you plan on incorporating additional tools or bending equipment, you should note that it increases the production cost of your aluminum extrusions. Working with a reputable extruder saves you the hassle of failed machinery and other issues that might increase the manufacturing cost.

Minimums have an impact on the overall extrusion cost. For this reason, you should have a reasonable range for the batches you can produce. In case a customer’s order is under this range, you can negotiate the cost, so it's a win-win situation.

The type of alloy for your project, design of the aluminum profile, and finishing solution are other factors that can affect the cost of the production process.

The establishment of businesses with aluminum requirements is skyrocketing, which calls for optimum efficiency machinery and cost-effective production. Traditional extrusion equipment won't cut it if you are seeking to keep up with the growing demand for aluminum profiles.

Recently, businesses that didn't open up possibilities for aluminum extrusions earlier on are giving it a shot. These profiles play a direct or indirect role in almost all industries. That said, at Wangeshi we strive to reduce the information gaps on the production process of aluminum extrusion, which is the leading factor why manufacturers exceed expenses, among other costly mistakes.

We make a difference in your products through our technological innovations in the aluminum sector. Whether you want energy efficient, top quality extrusion machinery suitable for standard or complex profiles or other extrusion equipment services, Wangeshi is the right company for the job.

Different features of aluminum extrusions, like the cross section, affect the amount of scrap and production cost; intricate profiles are more expensive to produce, while an increased amount of crap equals additional conversion expenses. Standard profiles are cheaper to produce, and the conversion is way cheaper.

Metal flow is the main determinant on whether the final product will meet the quality demand, or have defects. It can be affected by a wide range of factors. On the same note, there are different issues that might occur in between the initial production stage and the final finishing stage.

These problems often cause some sort of defect on the aluminum profile. Worry not if this occurs, as you can use the conversion technique to correct the defects and reduce scrap. The following defects can increase your production cost:

Surface Defects - There is a wide range of surface defects that can occur during the extrusion process. Think of die lines, scratching, score lines, pickups, etc. Most surface defects occur when a thin film of soft aluminum sticks on the surface of the die. When this thin film gets attached to a new billet on the die land, the defect occurs.

Metal Flow Defects - The extrusion tub can only hold a single billet at a go, to allow for a steady flow of the malleable metal. During the extrusion process, there are various factors that can affect the metal flow like changes in temperature and the length of the billet. You can prevent metal flow defects by ensuring the die has no shearing.

Welding Defects - Some modern aluminum extrusion machinery has a feeder ring that keeps the previous billet, allowing space for the next one. The issues that occur during this stage are known as welding defects. The longitudinal and transverse welds are examples of the likely defects.

Tooling Defects - Improper function of different components of the extruder, like the extrusion press, die, oven, etc., can cause defects, affecting the quality of the aluminum profiles. Some likely defects from this cause are black lines, bends, runout marks, rough surfaces, etc.

There you have it! We hope the information provided helps you navigate your aluminum extrusion process. If you are an extruder, it is crucial that you keep up with any predictable aspects of your production process and be on the lookout for those that are less obvious, like the cost of transportation and raw materials.

If you would like to get in touch with us concerning machinery or other requirements of your aluminum extrusion business, just give us a call or email. We are happy to help and super responsive.