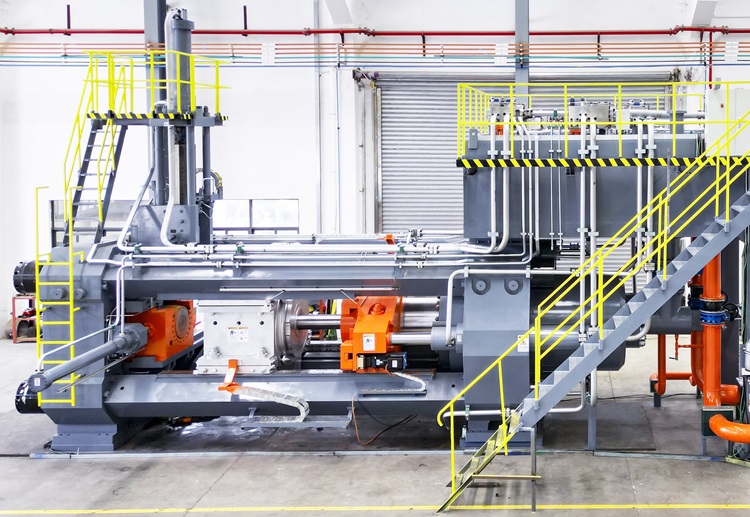

Aluminum profiles are usually the products of unique crafting primarily done by extrusion machines. The fantastic shapes, appearances, and size options are often associated with the type of extrusion machines used.

It is this factor that makes it essential to choose a superbly built, quality, and suitable extrusion machine for superior quality profiles.

Below is everything to keep in mind when choosing the ideal aluminum extrusion equipment.

As expected, there are numerous factors worth considering to land the suitable extrusion machine and tonnage of the equipment is among the most important. Typically, to identify the right tonnage, you need to start by calculating the machine’s extrusion ratio, usually called ‘extrusion co-efficient’. This is a term used to identify the ratio of aluminum's cross-sectional area to the machine’s barrel cross-section area. It is important because it determines the size of the end product which is the profile.

The extrusion’s tonnage usually signifies the overall extrusion force. Standard aluminum equipment has an average tonnage ranging from 500 tons to over 2000 tons. As earlier mentioned, the overall tonnage impacts the ultimate size of aluminum profile created. This means that the larger a machine is, the bigger the end product and vice versa.

Ultimately, the consideration of tonnage directly influences the overall size and of course quality of the profiles produced. With the proper tonnage, you can effectively generate quality, customer specific profiles to suit your customer requirements.

The extrusion machine market is packed with multiple forms of equipment usually categorized into various options based on factors like oil pressure, reverse, vertical, and even forward extrusion among others. This makes it essential to pick out a suitable option based on your intended purpose.

Ideally, as you choose your equipment, the machine’s model plays a vital part and it is usually based on the use and types of aluminum profiles you want to generate. For instance, there are various profile options like the industrial 6063-T5 option that is generated using forward horizontal (single-action) machines. Similarly, if you want soft pipe fittings, double-action direct horizontal machines are the model to go for.

It is important to pick the suitable extrusion machine model based on your needs, budget, and preferences. Nonetheless, the most popular machine is the single-action forward hydraulic model that is available in most industrial productions.

The other integral aspect to consider when buying extrusion machines is the standard extruder grade. Yes, once you’ve determined the suitable extrusion capacity and model of your machine, it is important to consider the grade.

Well, depending on your application, and your budget among other components, you can choose between a domestic and imported high grade extrusion machine. Ideally, if your production is medium-sized products, you can go for the domestic option with the imported one working well for top-grade profiles.

Ultimately, the extrusion grade is best determined by your budget and overall needs, among others and controls your efficiency in the final product generation.

Once you have made your choice on the model and tonnage, another important consideration worth making is the standard extrusion capacity your machine should have for optimal production. Typically, profile extruders come in diverse capacity options among them large, heavy, small, and medium extrusion power. The best way to identify the appropriate capacity for your needs is calculating the yearly production capacity based on its technical strength, sales conditions, production environments, and even standard of equipment.

The machine’s extrusion capacity varies because the output size and section size of the profiles is also different. Generally, the extrusion capacity usually ranges from around 150-over 1000MPa. The capacity necessary for your production is based on the scale of your production or what you intend to generate. Furthermore, the overall extrusion method also varies with forward types of extrusions mandating 1/3 more force compared to the reverse extrusion devices.

Our detailed review ends here with the knowledge that you can now safely walk into a shop and get yourself a top-quality extrusion device for your domestic and industrial applications. With understanding of these few factors, coupled with your needs and budget considerations, you are set for a successful purchase experience.