Guide on Improving Aluminum Profile Yield

Views:1309

Author:Site Editor

Publish Time:2023-10-11 10:27:33

Orgin:Site

share

In the aluminum profile manufacturing business where the profit margin is extremely tight, a 1% increase in the yield can be a significant factor raising up the profitability. By being able to conserve and optimize their resources, manufacturers can not only have a bumper production but also a strong bottom line.

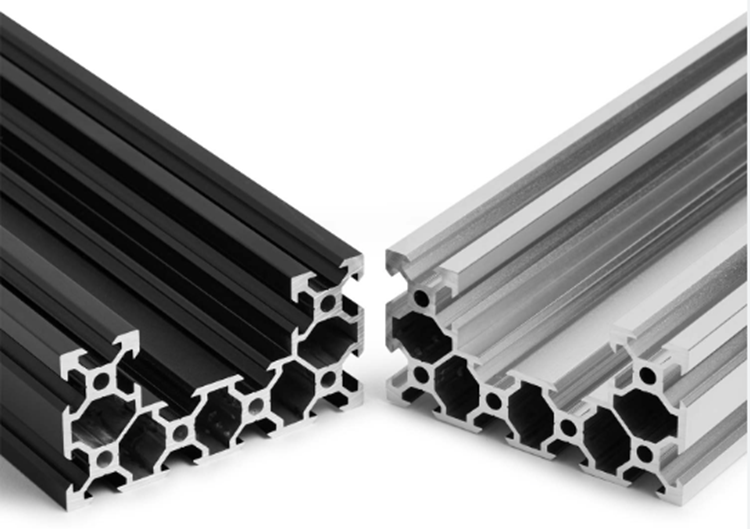

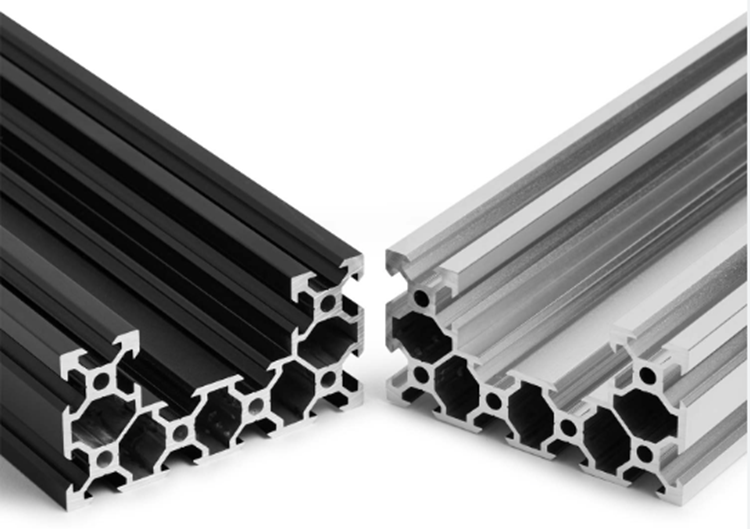

Understanding Aluminum Extrusion

Extrusion is a process in which the heated aluminum billet whilst be forced to pass through a specifically designed die. The shaping takes place by feeding the molten metal through the die producing complex profiles with equal dimensions. Though, there are some issues with the extrusion process which can result in losses. These are:

Improper Die Design: Die design which does not comply with the material flow rules can cause decline of smooth flow of material leading to profile inconsistency and defects. It can be due to their poor uniformity, unequal flow channels, sharp corners, or a miss-match of the requested shape and die geometry.

Subpar Material Selection: Deciding for an aluminum alloy without proper properties may happen to bring about the upsurge of scraps. The factors of strength, corrosion, and formability must be kept in mind while selecting material for any component.

Ineffective Material Handling: Deficient storage, handling or transporting of raw materials could be the contribution of contamination, destruction of billets or wetness absorption/oxidation. Such problems have adverse effects on output and increases the loss.

Tooling and Equipment Issues: A bad key, nonfunctional mandrels or equipment that is not being kept in good condition can lead to profile inconsistencies and defects during production. The tool life and quality of performance highly depend on inspection and maintenance.

Inadequate Quality Control: A good way through which a proper quality control regulation could be passed would be through making the profiles that are defective to be passed unnoticed. On the other hand, this not only generates scrap but also affects the appearance and product quality.

Strategies for Enhancing Yield

Here's a breakdown of key strategies: Here's a breakdown of key strategies:

Process Optimization

- Die Design Optimization: Designing dies with the helpof top-notch software and contributing to other skillful die designersresults in the production of dies that guarantee normal material flow.There will be no internal stresses and ensure the process of extrusionthat is effective.

- PrecisionTemperature Control: Integrity of the material flow depends on the exacttemperature settings; hence reductions in temperature variance arerequired to produce defect less metal flow during the extrusion process.Invest in high-performance temperature controls and pyrometers for processcontrol and accurate measurement.

- Extrusion Speed Optimization: The extrusion process flow isaffected by the complexity of the profile and the properties of thematerial thereby the adjustment of the extrusion speed is important. Consequently,higher extrusion speed can create surface faults while the slowness maybring about uneven flow of materials and internal cracks.

Material Selection and Handling

- Selecting the Right Alloy: The key to successful alloyselection for aircraft parts is in the strategic application of an alloythat will have exactly the right combination of strength, formability, andother necessary features. Meeting the demanded specification will beensured only through cooperation with the material suppliers and tappingin to the experience of metallurgists.

- Controlled Environment Storage: Moisture and fat oxidationprevention can avoid rupturing of billet structure. You may have totherefore keep temperature and ambient air constant.

Tooling and Equipment Management

- Preventative Maintenance: The Inspection &Maintenance is regularly performed on dies, mandrels, containers, andother equipment checking the level of their functional efficiency andpreventing defects caused by well-used tooling.

- Die Wear Monitoring: Regarding this issue, it isnecessary to not get away from scheduled die monitoring and measuring tokeep a consistent profile of the part. Replacing or refurbishing dies asnecessary when noticing significant deviations from the specificationsrequired eliminates a substantial amount of unnecessary work.

- Friction Reduction: Combining the entire systemwith the appropriate lubricants and support tools such as the mandrel anddummy blocks that were designed properly can help in reducing the frictionduring the extrusion process and this leads to more uniform material flowand yield.

Quality Control and Inspection

- Implementing Robust InspectionProcedures:Implementing detailed visual, and dimensional checks at different stagesthroughout the extrusion process would lead to early discovering ofsuperficial aberrations like scratches, dents, or non-uniformity of thesurface.

- Non-Destructive Testing: The application ofnon-destructive techniques like ultrasonic or eddy current testing canexpose internal defects such as cracks and voids that are not scooped bythe surface examination. It allows us to filter out any flaws in thecreated prototypes that are selected for manufacturing proceedings.

Conclusion

Yielding aluminum profiles optimally involves a multi-dimensional approach. Through developing these extensive methodologies and of course, sustaining the necessary adjustments, aluminum profile manufacturers can realize the lost yield as production efficiency, reduced wastage, and obviously, enhanced bottom line.